Open & Close Oilfield Equipment's

- Introduction

- Accumulators

- Workovers

- Testing Units

- Accessories

Open And Close Equipment

Open And Close Equipment geared to offer the oil industry a wide variety of Both standard and custom units that will fit your needs. Our facility located in Rosenberg, Texas USA manufacture, assemble, and fabricate these units. Feel free to contact us for your next Request for Quote.

Open and Close Equipment offers:

- Accumulator units

- Workover units

- Test units

- Repair kits

- Accessories

- Replacement parts

Just ask GTO for a quote, and you will get:

- Service to meet your needs.

- Quality to meet API 6A, 16A, & 16D certification

- Delivery to anywhere in the world

Open And Close Equipment

Open And Close Equipment geared to offer the oil industry a wide variety of Both standard and custom units that will fit your needs. Our facility located in Rosenberg, Texas USA manufacture, assemble, and fabricate these units. Feel free to contact us for your next Request for Quote.

Open and Close Equipment offers:

- Accumulator units

- Workover units

- Test units

- Repair kits

- Accessories

- Replacement parts

Just ask GTO for a quote, and you will get:

- Service to meet your needs.

- Quality to meet API 6A, 16A, & 16D certification

- Delivery to anywhere in the world

ACCUMULATORS

3 Station 6 Bottle Accumulator With Electric Motor

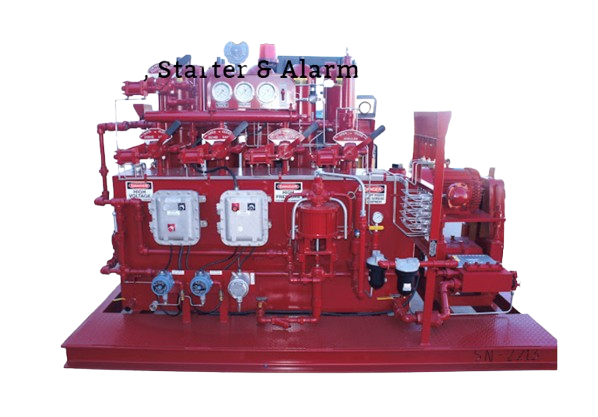

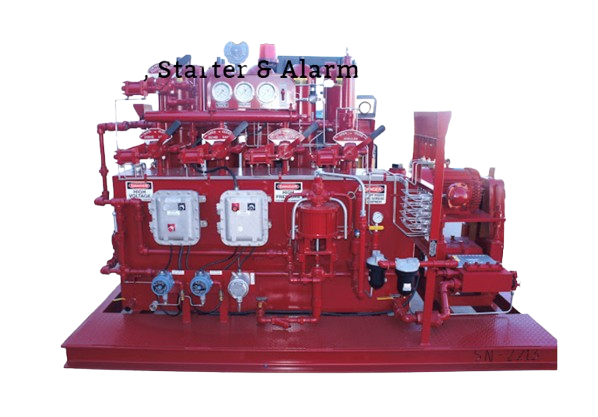

4 Station 10 Bottles with Electric Engine, Starter & Alarm System

5 station 10 bottles with Diesel Engine Accumulator Unit

6 Station 20 Bottles Hydraulic over Pneumatic System Accumulator Unit

6 Station 16 Bottles with Diesel Engine & Auto Starter Accumulator Bottlers

6 Station 24 Bottles Accumulator Unit with Alarm System

8 station 20 bottles with Electric Motor Accumulator Unit

9 Station 24 bottles with Electric Engine & Alarm System Accumulator Unit

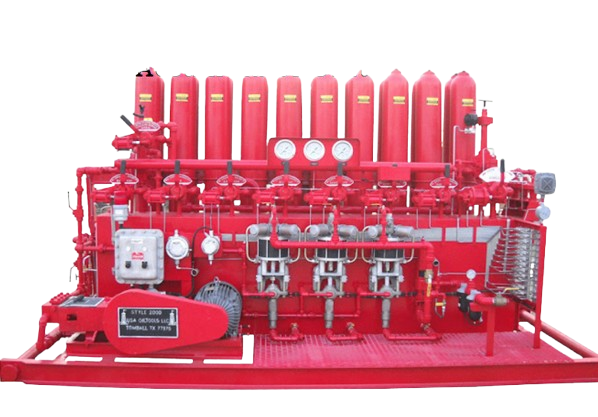

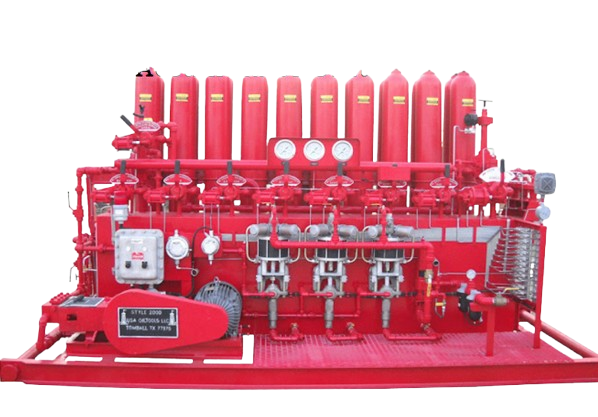

12 Station 20 Bottles with Electric Motor Accumulator Unit

Accumulator with Remote PLC System

6 Station 24 Bottle Accumulator With Allen Bradley PLC

8 Station 24 Bottle Accumulator With Siemens PLC

9 Station 36 Bottle Accumulator With 2 Electric Engines And Siemens PLC

10 Station Bottle Rack Accumulator Unit With PLC And Diverter

40 Bottles Rack 15 Gallon 5000 psi.

ACCUMULATORS

3 Station 6 Bottle Accumulator With Electric Motor

4 Station 10 Bottles with Electric Engine, Starter & Alarm System

5 station 10 bottles with Diesel Engine Accumulator Unit

6 Station 20 Bottles Hydraulic over Pneumatic System Accumulator Unit

6 Station 16 Bottles with Diesel Engine & Auto Starter Accumulator Bottlers

6 Station 24 Bottles Accumulator Unit with Alarm System

8 station 20 bottles with Electric Motor Accumulator Unit

9 Station 24 bottles with Electric Engine & Alarm System Accumulator Unit

12 Station 20 Bottles with Electric Motor Accumulator Unit

Accumulator with Remote PLC System

6 Station 24 Bottle Accumulator With Allen Bradley PLC

8 Station 24 Bottle Accumulator With Siemens PLC

9 Station 36 Bottle Accumulator With 2 Electric Engines And Siemens PLC

10 Station Bottle Rack Accumulator Unit With PLC And Diverter

40 Bottles Rack 15 Gallon 5000 psi.

WORKOVERS

Open And Close Equipment’s Workover Units meet design specifications specified in API 16D. Workover units have been an industry staple for over 30 years for performing well workovers that require large diameter workover strings, or operating the workover under high pressures, or both. Here are some standard units that can also be customized to meet your needs.

Portable Units

3 Station 4 Bottles with 2 Gas Engines - Starter Box - Alarm System - Nitrogen Bottles & Pedestal Panel

3 Station 4 Bottles with Gas & Air System Trailer Mounted Workover Unit

4 Station 4 Bottles with 2 Diesel Engine - Alarm System & Nitrogen Back Up

4 Station 8 Bottles with 2 Diesel Engine - 2 Auto Starter - Nitrogen Bottles & Panel

3 Station 4 Bottles with 2 Gas Engines - Starter Box - Alarm System - Nitrogen Bottles & Pedestal Panel

3 Station 4 Bottles with Gas & Air System Trailer Mounted Workover Unit

4 Station 4 Bottles with 2 Diesel Engine - Alarm System & Nitrogen Back Up

4 Station 8 Bottles with 2 Diesel Engine - 2 Auto Starter - Nitrogen Bottles & Panel

Standalone Units

3 Station 4 Bottles with Gas Motor & Triplex Pump Workover Unit

3 Station 4 Bottles with Gas Motor Workover Unit

3 Station 4 Bottles with Nitrogen Bottles - Diesel Engine & Auto Starter Box Workover Unit

3 Station 4 Bottles with Gas Motor & Triplex Pump Workover Unit

3 Station 4 Bottles with Gas Motor Workover Unit

3 Station 4 Bottles with Nitrogen Bottles - Diesel Engine & Auto Starter Box Workover Unit

TESTING UNITS

Open And Close Equipment’s Accumulator Units meet design specifications specified in API 16D. Each control system is expertly engineered, assuring reliable control of the BOP stack with adequate reserve for continuous operation under emergency conditions.BOP closing units also known as Accumulator Units range in a variety of sizes. These units come standard with air/electric over hydraulic design but can also be delivered as a diesel driven setup.Here are some standard designs which can be customized to meet your needs.

New Models

Hydrostatic Test Unit with electric pump up to 15000 psi Includes Hydraulic Pump with regulable control for high torque wrench

10,000 psi with Triplex Pump Enclosured

Test Unit with Electric Motor, Pneumatic System & Bottles

Test Unit with Gas Motor

Test Units

Compact

OCC10RA 10,000

OCC15RA 15,000

OCC20RA 20,000

OCC30RA 30,000

Fixture

OCF10RA 10,000

OCF15RA 15,000

OCF20RA 20,000

OCF30RA 30,000

Self - Contained

OCHT10RA 10,000

OCHT15RA 15,000

OCHT20RA 20,000

OCHT30RA 30,000

Portable

OCP5GRA 5,000

OCP6RA 6,000

OCP10RA 10,000

TESTING UNITS

Open And Close Equipment’s Accumulator Units meet design specifications specified in API 16D. Each control system is expertly engineered, assuring reliable control of the BOP stack with adequate reserve for continuous operation under emergency conditions.BOP closing units also known as Accumulator Units range in a variety of sizes. These units come standard with air/electric over hydraulic design but can also be delivered as a diesel driven setup.Here are some standard designs which can be customized to meet your needs.

New Models

Hydrostatic Test Unit with electric pump up to 15000 psi Includes Hydraulic Pump with regulable control for high torque wrench

10,000 psi with Triplex Pump Enclosured

Test Unit with Electric Motor, Pneumatic System & Bottles

Test Unit with Gas Motor

Test Units

Compact

OCC10RA 10,000

OCC15RA 15,000

OCC20RA 20,000

OCC30RA 30,000

Fixture

OCF10RA 10,000

OCF15RA 15,000

OCF20RA 20,000

OCF30RA 30,000

Self - Contained

OCHT10RA 10,000

OCHT15RA 15,000

OCHT20RA 20,000

OCHT30RA 30,000

Portable

OCP5GRA 5,000

OCP6RA 6,000

OCP10RA 10,000

ACCESSORIES

Open And Close Equipment’s accessories meet design specifications specified in API 16D

Duplex & Triplex Pumps

5 to 60 HP – 3000 psi – Voltage: 230, 480, 380, & 575

Air Operated Hydraulic Pumps

Ratio: 30:1 | 50:1 | 60:1 | 140:1 | 200:1 | 300:1

8 1/2″

8 1/2″

7 3/8″

6″

8″

Hydraulic Regulator Valves

Manual

Hydraulic

Fail Safe Motor

Pneumatic Pilot

Bladder Accumulator

Electronic Remote Panels

Air Remote Panels

Master

Auxiliary

Small Auxiliary

Hydraulic Control Valves

Hydraulic Pressure Fittings

Various Accessories

ACCESSORIES

Open And Close Equipment’s accessories meet design specifications specified in API 16D

Duplex & Triplex Pumps

5 to 60 HP – 3000 psi – Voltage: 230, 480, 380, & 575

Air Operated Hydraulic Pumps

Ratio: 30:1 | 50:1 | 60:1 | 140:1 | 200:1 | 300:1

8 1/2″

8 1/2″

7 3/8″

6″

8″

Hydraulic Regulator Valves

Manual

Hydraulic

Fail Safe Motor

Pneumatic Pilot

Bladder Accumulator

Electronic Remote Panels

Air Remote Panels

Master

Auxiliary

Small Auxiliary

Hydraulic Control Valves

Hydraulic Pressure Fittings

Various Accessories